Introduction: Say Goodbye to Fragmented Supply, Embrace Integrated Efficiency

For global eyewear brands pursuing excellence, the complexity of eyewear packaging supply chains often becomes an invisible burden on growth. Coordinating scattered suppliers of eyewear cases, gift boxes, paper shopping bags, cleaning cloths, and printed materials not only drives up communication costs but also jeopardizes brand consistency, quality control, and delivery timeliness.

We offer a fundamental solution: a one-stop, complete eyewear packaging suite. As your sole eyewear packaging solution partner, we integrate every step from design to delivery, providing fully unified, quality-controlled packaging sets with significantly optimized management costs. This article illustrates how our system simplifies complexity through a case study with a leading Korean fashion eyewear brand, empowering brands to focus on core growth.

How did we transform the supply chain for this Korean fashion brand?

Challenge: The classic dilemma of multi-supplier management

At the outset of our partnership, the brand faced an industry-wide challenge: managing over five distinct suppliers responsible for leather eyewear cases, paper shopping bags, fabric pouches, top-and-bottom boxes, and printed materials like manuals, cards, and sleeves. This resulted in:

1. Brand consistency was difficult to guarantee: Variations in craftsmanship standards and color management across suppliers.

2. Persistently high hidden costs: Multiple communication channels, separate logistics, and fragmented quality control consumed substantial management resources.

3. Unpredictable project timelines: Delays at any stage disrupted overall launch, promotion, and sales schedules.

Our Role: To become the exclusive provider of integrated eyewear packaging solutions.

Upon engagement, we transition from a “single-product manufacturer” to a “holistic solution steward.” Eyewear brands need only coordinate with our single team to achieve synchronized production and delivery of all packaging components.

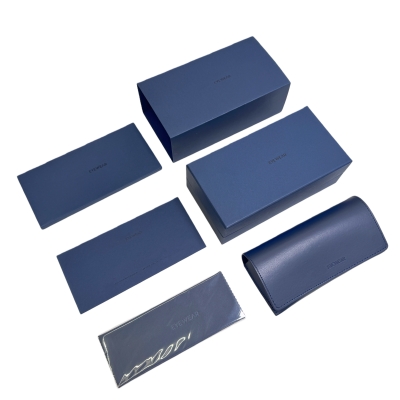

Solution Overview: A Fully Integrated Suite

The complete suite we designed and produced for this eyewear brand comprises the following highly coordinated components, all adhering to a unified brand visual identity system:

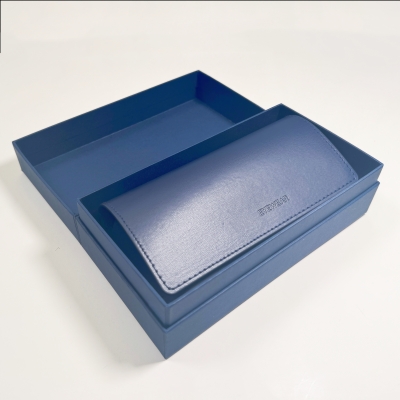

Custom Leather Eyeglasses Case

100% eco-friendly PU leather with ultra-soft premium plush fabric provides daily top-tier protection and a luxurious feel.

Heaven and Earth Lid Gift Box

Crafted from heavyweight specialty paper with a matte laminate finish and precision foil stamping, delivering a luxurious retail unboxing experience.

Heaven and Earth Lid Exclusive Paper Sleeve

A visual focal point bridging past and future, reinforcing the brand identity’s first impression.

Eyewear Cloth

Microfiber fabric, 250g, double-sided brushed finish, individually packaged. Combines practical functionality with brand visibility.

Instruction Manual and Sleeve

A carrier for professional product information, crafted with the same paper and techniques as the outer box to reflect meticulous attention to detail.

Eco-Friendly Shopping Paper Bags

Complete the final loop of your brand experience. Ideal for retail settings, these bags elevate your brand’s eco-conscious image.

Canvas Shopping Bag

340g canvas bag, ideal as a promotional gift for clients. Custom printing of your brand logo serves as advertising during client use.

Quantified Results: Dual Enhancement in Efficiency and Brand Value

By adopting our “Complete Eyewear Packaging Sets” solution, the brand achieved:

100% Brand Visual Consistency: Perfectly unified brand image across all touchpoints.

Approximately 35% Reduction in Supply Chain Management Costs: Savings from eliminating multi-vendor coordination, independent logistics, and quality inspection expenses.

25% reduction in overall project cycle time: Integrated production scheduling eliminated component waiting periods.

Strategic Focus Shift: Teams freed from complex supply chain management to concentrate on market expansion and product design.

Our Service Process: Seamless Collaboration from Concept to Delivery

We’ve systematized this successful model to provide you with clear, reliable end-to-end services:

Requirement Diagnosis & Planning

We deeply understand your brand positioning, target market, budget, and timeline to jointly plan the optimal kit configuration.

Integrated Design & Engineering Development

We establish cross-functional and technical teams to collaborate, delivering holistic design solutions covering all components and conducting structural engineering feasibility analyses.

Integrated Production & Quality Control

All components are manufactured under coordinated scheduling, with unified monitoring by dedicated teams to ensure compliance at every stage.

Consolidated Packaging & Global Logistics

After quality inspection, all accessories are packaged as complete sets. We offer diverse international logistics solutions to ensure you receive your order intact and complete in one shipment.

Our core value lies in: a single point of contact, unified responsibility, transparent total cost, and a seamless experience.

Start Your Simplification Journey Today

If your eyewear brand is struggling to manage multiple packaging suppliers or seeking a case packaging solution for new collections that ensures brand integrity, our “One-Stop Complete Solution” is designed for you.

We invite you to take the first step toward streamlining your supply chain.

Provide your eyewear brand’s basic information and requirements, and our solution specialists will deliver a preliminary “Customized Turnkey Solution Plan and Budget Assessment” within 24 hours.

Let packaging become a catalyst for your brand’s growth, not a burden.

Want to dive deep into the decision-making details of packaging materials and processes? Read our industry Ultimate Guide.

https://www.xhglassescase.com/the-definitive-guide-to-custom-eyewear-packaging-case-manufacturing-2026/

1. Q: What is a “one-stop eyewear packaging solution”?

A: A one-stop eyewear packaging solution refers to a single supplier integrating the production of all packaging components, including eyewear cases, top-and-bottom lid gift boxes, branded paper sleeves, microfiber cleaning cloths, instruction manuals and sleeves, eyewear cleaning solutions, shopping paper bags, and canvas shopping bags. By working with just one team, you achieve fully unified brand visuals and integrated quality control—eliminating the need to coordinate with five or more separate suppliers.

2. Q: How does choosing a complete packaging supplier save my brand hidden costs?

A: Take our Korean fashion eyewear brand client as an example. After adopting complete packaging procurement, supply chain management costs decreased by approximately 35%, and overall project cycles shortened by 25%. These savings primarily stem from: eliminating multi-supplier communication time, consolidating independent logistics costs, freeing up分散 quality control resources, and eliminating the risk of shelf delays caused by delivery schedule synchronization issues.

3. Q: What is the minimum order quantity (MOQ) for custom eyewear packaging boxes?

A: We offer flexible MOQ policies for our integrated solutions. For complete sets including multiple components like eyewear cases, gift boxes, and paper bags, the MOQ typically ranges from 1,000 to 2,000 sets. We also provide tiered MOQ options tailored to your brand stage and project budget, enabling small-to-medium brands to launch professional eyewear packaging at reasonable costs.

4. Q: What specific components are included in the complete eyewear packaging set? Can I select only certain items?

A: Our standard suite includes: custom leather/PU eyewear case, top-and-bottom lid gift box, branded paper sleeve, microfiber cleaning cloth, instruction manual, eyewear cleaning solution, eco-friendly paper shopping bag, and canvas tote bag. You may freely combine or remove components based on your product positioning and channel requirements. For instance, the e-commerce version can omit the outer paper bag, while the retail flagship version may add premium features like magnetic window boxes.

5. Q: How do you ensure color consistency across different components (leather cases, paper boxes, fabric items) aligns perfectly with brand visuals?

A: We employ a comprehensive color management system. From leather dyeing and paper printing to fabric embroidery, all processes use Pantone color codes as the unified standard. Whenever possible, dyeing is coordinated within the same factory. This creates a quality barrier unattainable through decentralized sourcing—as demonstrated in our Korean client case, where we achieved 100% brand visual consistency across all components.

6. Q: What is your typical lead time? Can you accommodate new product launch schedules?

A: For established product lines (e.g., Deep Sea Blue series), initial prototyping takes approximately 7-10 business days. Mass production cycles range from 25-35 days, depending on component complexity and order volume. We offer capacity reservation mechanisms for contracted annual partners, ensuring your new product launches remain unaffected by supply chain fluctuations.

7. Q: What is the “ink-sealed edge” process? Why is it crucial for premium eyewear cases?

A: Ink edge sealing is a signature technique for premium leather eyewear cases. It involves precision laser cutting to create smooth edges, followed by hand-applying matching paint and repeated polishing to achieve a rounded, refined texture. Standard die-cutting produces fibrous frayed edges incapable of this effect. This process directly determines the case’s “luxury feel” and durability.

8. Q: Do you support eco-friendly material customization?

A: Yes. We offer sustainable options including FSC-certified recycled cardboard, PU leather (REACH compliant), biodegradable liners, water-based ink printing, and eco-friendly water-based adhesives. You can integrate sustainability into your packaging design without compromising unboxing quality. We have successfully delivered multiple batches of eco-material kits for Italian clients.

Post time: Feb-10-2026